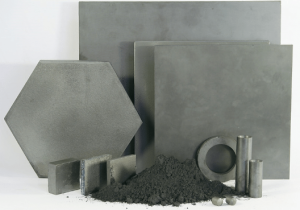

can supply high quality B4C for grinding & polishing of LED display and sapphire, also can use for refractory materials. Boron carbide annual production capacity is 2,000MT, including extremely pure B4C, B4C of high content of boron, B4C of high content of carbon. The crushing and sieving line and micro powder production line provide an annual capacity of 800 MT of finished materials. We supply Boron carbide grain or micro powder produced by the standard of GB/T 2481, FEBA or JIS. We also offer super fine powder (< 2µm) and special powder for engineering ceramics and nuclear industry.

Boron Carbide Applications

Superior Abrasives

For polishing materials, abrasive water jet cutting and diamond abrasive material amendments.

Bulletproof armor material

Used for bulletproof armor material – make bulletproof material, such as bulletproof vests bulletproof plates, military aircraft cockpit bulletproof ceramic tiles and modern armored personnel carriers and tanks, ceramic bulletproof plate.

Advanced Refractory

For the refractory industry, such as antioxidant additives for carbon brick.

Nuclear Material Control

Nuclear Material Control

Making nuclear reactor control rods and closed columns, making for radiation protection of boron carbide tile, sheet or neutron absorber (B10 with a high content of powders), or mixed with cement for the production of nuclear reactor shield.

As industrial ceramic materials

As industrial ceramic materials

Making other engineering ceramic materials, such as sand blasting nozzle cutting machine, sealing rings, ceramic mold and other nozzles, high pressure water.

Alloy powder

Alloy powder

For electrodes, in order to enhance abrasion resistance weld surface.

| Category | Particle size | Technical indicators | Usage |

| interval sand | 40#-120#,60#

-150#,90#-220# |

B4C>95.5%

B 77-80% C 17-19.5% |

raw materials for reprocessing |

| Grain sand | F40,F46,F54,F60,F70,

F80,F90,F100,F120 |

boronizing(See description) | |

| F150,F180,F220 | Grinding & polishing of LED display and sapphire | ||

| Micro powder | F240,F280(W63),F320

(W50) |

B4C>95%

B 75-79% C 17-19.5% |

grinding & polishing of LED display and sapphire;making other ceramic products;raw materials for anti-ballisticproducts |

| F360(W40),F400(W28)

F500(W20),F600(W14) |

B4C>95%

B 76-80% C 17-19.5% |

||

| F800(W10),F1000(W7)

F1200(W5),F1500(W3.5) |

B4C>95%

B 74-76% C ≥20% |

||

| Powder(325F) | 44μm-0 | B4C>95%

B 76-81% C 17-20.5% |

Anti-oxidant in carbon-bonded refractory mixes |