Brown fused alumina introduced

Brown fused alumina is with bauxite, Jiao Tan (anthracite) as the main raw material

in the electric arc furnace from high temperature smelting, grinding tools made of it are suitable for grinding, high tensile strength of metal, such as a variety of common steel, malleable cast iron, hard bronze, also can manufacture high-grade refractory materials.

Brown corundum powder has high purity, good crystallinity, high liquidity, low coefficient of linear expansion, corrosion resistance.

After dozens of refractory production enterprise practice verification, this product has the characteristics of no initiation, not pulverization, no cracking in the application process. Especially the far higher than traditional brown corundum price, more make it become the best corundum refractory aggregate and filler.

Brown fused alumina industry application

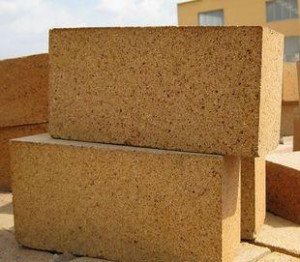

Brown fused alumina refractory

Brown fused alumina refractory

Corundum refractory brick used in normal temperature compressive strength is very high (up to 340MPa), high load softening start temperature (higher than 1700 DEG C), excellent chemical stability, resistance to acid or alkaline slag, metal and glass liquid had strong. Mainly used in blast furnace and the hot blast furnace, ladle furnace refining furnace, water heater, sliding glass furnace as well as the petroleum chemical industrial furnace.

Brown fused alumina Use Castable

Brown fused alumina Use Castable

Iron casting material

Suitable for large, medium-sized blast furnace iron groove has a plurality of taphole of main slag line area, hot metal area, ditch, slag ditch, ditch lining swing.

The ladle pouring material

The working lining and other parts used in ladle molten operation, launder and various furnaces, with very high strength and refractoriness, and excellent impact resistance, anti erosion, anti permeability, wear performance.

Lightweight refractory castable

Light weight castable is suitable for steam boiler, oil industry pipe type heating furnace, light diesel oil, ethane cracking furnace, oil catalytic cracking unit of heat preservation heat insulation layer structure; industrial furnace insulation lining, pipework insulation lining, cooling machine system insulation lining, dust collector internal insulation lining etc..

Mud gun

Is mainly used to steady the taphole, protection, protection of iron crucible, divided into water stemming, anhydrous stemming.

Sand blasting

Sand blasting

Abrasive hardness modest, high bulk density, no free silica, more than major, good toughness, is the ideal “green” type sandblasting materials, widely used in aluminum,copper profile of glass, washed jeans precision mold and other fields;

Abrasive materials

Level grinding abrasive, applied to the picture tube, optical glass, monocrystalline silicon, lens, clock and watch glass, crystal glass, jade and other field free grinding, issenior grinding material widely used in home;

Resin abrasives

Abrasive color right, good hardness, toughness, suitable particle section type and edgeretention, used in resin abrasive, ideal effect;

Coated abrasives

Abrasive sandpaper, gauze and other manufacturers of raw materials production;

The functional fillers

Mainly used for automobile brake parts, special tires, special building products such as collar can be used as construction of highway pavement. The runway at pier. Parking. Industrial flooring sports venues and other wear-resistant materials;

The filter medium

Is a new application field of abrasive, the underlying medium using granular abrasive filtrating bed, purifying drinking water and waste water, is a new kind of filter material at home and abroad, especially suitable for non-ferrous metal processing: drilling mud weighting agent:

Hydraulic cutting

Is abrasive for cutting medium, water jet cutting basic, applied to Petroleum (natural gas) cutting pipe, steel and other components, is a cutting model, environmental protection, security.

| Product ategory | Particle size | Technical index | Usage |

| Bonded Abrasives | F24,F30,

F36 |

F16-F100(P24-P100):

Al2O3>95.0% SiO2<1.0% Fe2O3<0.15% TiO2<2.3-2.9% CaO+MgO<0.9% F120-F220(P120-P220): Al2O3>94.5% SiO2<1.2% Fe2O3<0.2% TiO2<2.5-2.9% CaO+MgO<1.0% |

Mainly used for manufacturing bonded abrasives such asvitrified abrasive wheel, resin-bonded grinding wheel, cutting disc, oilstone, etc. |

| F16,F20,

F22,F40, F46 |

|||

| F54,F60,

F80 |

|||

| F70,F90,

F100,F120 |

|||

| F150,F180,

F220 |

|||

| Coated Abrasives | P24,P30,

P36,P220 |

Mainly used for manufacturing coated abrasives such as sanding belt, handwork sanding paper and abrasive cloth, etc. | |

| P40,P50,

P60,P80 |

|||

| P100,P120,

P150,P180 |